Resources

Manufacturing capabilities

Metals

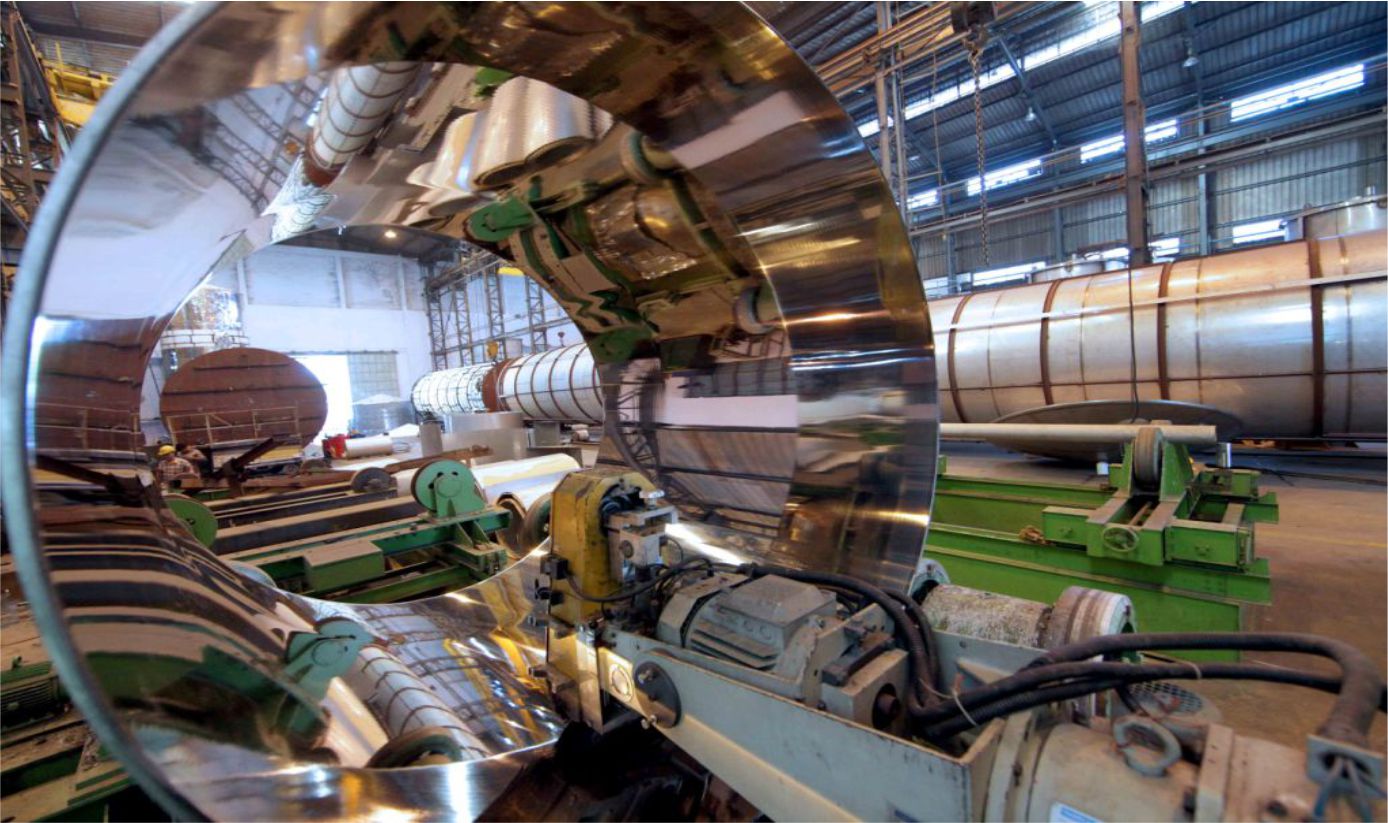

IDMC’s metal fabrication and machining facilities are spread over approximately 30,000 square meters. The company’s automatic polishing facility together with water jet cutting and dish spinning facilities provide uniform surface finish on vessels and cutting-edge in job quality.

IDMC’s machine shop is equipped with several CNC machining centres. The machine shop caters to the machining requirement of other fabrication shops and manufactures a complete range of sanitary fittings, unions, tri-clover clamps, tees, butterfly, plug and pneumatic valves, turbo blenders, pumps, ice-cream freezers, homogenizers, and cup filling machines.

IDMC is a leading manufacturer of tankages, process vessels, plate heat exchangers, flow items and specialized key process equipment. A significant part of IDMC’s growth has been through the Supply, Installation, Testing and Commissioning (SITC) of projects in the dairy, pharmaceuticals, beverages sector and Thermal Management Systems. IDMC diversified into turnkey projects with the setting up of cattle feed plants in 2011.

All the facilities have the capability to manufacture equipment in compliance with the most stringent requirements of various countries viz. CE, EN, FDA, etc. The facilities are also ISO 9001 – 2008 and ASME certified.

Engineering is the backbone of our offerings. More than 70% of the employees are engineers in various disciplines – mechanical, chemical, electrical, civil, instrumentation, etc.

With knowledge and experience coupled with the latest design software, the engineering team ensures accuracy and smooth interfacing between various modules of an integrated plant.

Plastics

The FSSC 22000 certified packaging film plant of IDMC is spread over more than 11,000 square meters. The facility provides packaging solutions in the form of food-grade packaging films, laminates, and pouches (with low permissible thickness, high clarity and barrier properties) to its customers in various sectors such as dairy, edible oil, food, pet-food, seeds, personal-care products and fruit concentrates.

In view of the growing demand for high barrier films, IDMC has installed a modern seven-layer co-extruded blown film plant. The company is looking to expand its customer base by developing new customers in UHT milk, cheese, ghee, edible oil, and other food products.

Quality assurance

Metals

IDMC has a well-equipped inspection facility and test laboratories with skilled manpower to meet quality standards of products, projects and services at every stage. Certified quality management and food safety systems assure continuous improvements.

Plastics

The quality assurance lab is equipped with sophisticated instruments including Gauge Profile Analyzer, Gas Chromatograph, Universal Testing Machine, Co-efficient of Friction, Melt Flow Index, Opacity Tester, Dart Impact, Bar Code Verification, Gloss Meter, and Spectro Photo Meter to test and analyze raw materials, intermediate products and finished goods. GFSI recognized Food Safety System Certification ensures world-class practices and continuous improvement.