Flow

products

Pumps

The transfer of liquid from one process to another, like storage to processing and packing is an essential activity in a processing plant. The liquid transfer in the dairy industry needs to be hygienic and gentle, with low pressure drop to ensure no quality damages. The key components needed for a flow system are pumps and piping. IDMC’s pumps comply with EHEDG and 3A standards.

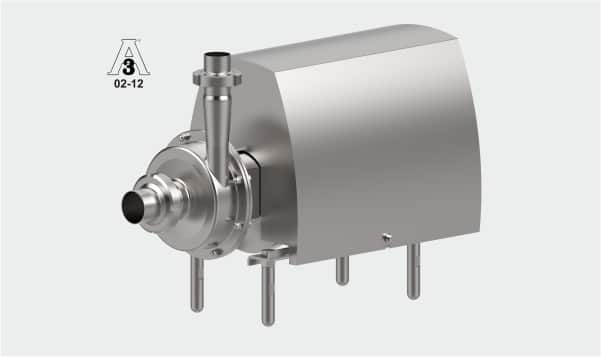

Sanitary centrifugal pump

IDMC has a comprehensive range of high performance sanitary centrifugal pumps with close impellers. These pumps are ideally suited for dairy, beverage, pharmaceutical and cosmetic industries. All the parts coming in contact with the product are made of AISI 316L stainless steel. The centrifugal pumps have unique features;

- Standard motor can be used.

- Possible to have a single seal design or double mechanical seal. design with seal cooling arrangement.

- The impeller vanes are three dimensional.

- Common mechanical seal across all the models of pumps.

Self priming centrifugal pump

The self priming pumps are generally used for CIP return function. The unique design of IDMC self priming pump ensures that the casing is always filled with fluid.

The pumps are similar to the sanitary pumps with a different and special casing. These pumps are ideally suited for dairy, beverage, pharmaceutical and cosmetic industries. All the parts coming in contact with the product are made of AISI 316L stainless steel. The centrifugal pumps have unique features:

- Standard motor can be used.

- The impeller vanes are three dimensional.

- Common mechanical seal across all the models of pumps.

Shear pump

The centrifugal shear pumps are used for disintegration of suspended solids to very small size particles in any product. Generally, these are used for making buttermilk. It is possible to have the size of curd particles ranging from 10 microns to 25 microns.

The shear pumps are available with three different types of shearing heads, as per the product requirement.

Lobe pumps

IDMC lobe pumps are positive displacement pumps of efficient sanitary design and suitable for dairies, food processing, beverages, and pharmaceutical industries. Due to its low working speed, the rotary lobe pump is characterized by gentle pumping thereby causing low shear of the product. All parts coming in contact with the product are made of AISI 316 and/or AISI 316L stainless steel.

Side-entry agitator (ISHA Series)

IDMC offers side entry agitators that can mix large volumes of liquid in a homogeneous and efficient way. These devices can prevent sedimentation and maintain temperature uniformity in large tanks. They can be conveniently installed at any position along the side of the mixing tank/vessel. IDMC-make side entry agitators that are suitable for 20KL to 150 KL tank/vessel. They have a specially designed hydrofoil impeller that creates an axial flow without turbulence, resulting in better mixing efficiency with low power consumption.

Some of the benefits of a side entry agitator over a vertical agitator are:

- Lighter in weight.

- Easier to mount.

- More energy efficient.

- Low RPM.

- Easier to transport.

Turbo blenders

The turbo blenders are used extensively for recombination and reconstitution in food and non-food industries. This versatile equipment by IDMC is suitable for several other solid-liquid or liquid-liquid mixing. All parts coming in contact with the product are made of AISI 304 stainless steel and/or AISI 316L.

Available capacity: Upto 3500 kgs/hr