Processing & packaging solutions to make food safe

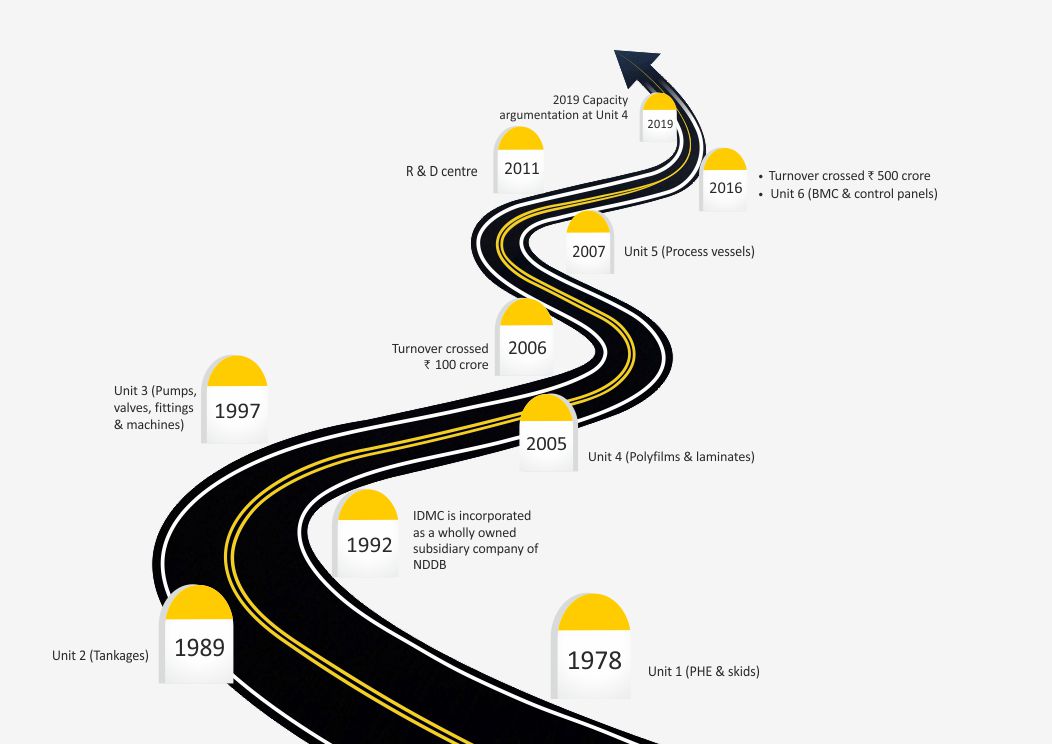

IDMC was incorporated in 1978 to indigenously manufacture dairy components and equipment in a cost-efficient manner.

About us

IDMC became a wholly owned subsidiary of National Dairy Development Board (NDDB) in 1992. Over the years, IDMC’s Making in India initiative has led to a significant growth in its manufacturing base and reduced the dependence of the domestic dairy industry on the import of a large number of diverse dairy equipment.

Design expertise

IDMC’s design group has led its growth and contributed to establishing quality systems for pressure equipment according to European directive 97/23/EC, module D, duly certified by TUV Nord. IDMC has also exported engineering products with U-stamp, an accreditation by the American Society of Mechanical Engineers. IDMC has QMS ISO 9001 certification for five units that manufacture metal products.

Project engineering & execution

A significant part of IDMC’s growth has been through the Supply, Installation, Testing and Commissioning (SITC) of projects in the dairy, pharmaceutical, beverage sectors and Thermal Management Systems.

The company also offers consultancy services, ensuring a remarkable efficiency and consistency in plant design and execution. IDMC undertakes turnkey projects for setting up cattle feed plants.

Highly experienced engineers supervise skilled technicians to execute mechanical, electrical, process and piping installations including automation.

Advanced tools such as orbital welding machines are employed to achieve welds conforming to the latest international standards. To its credit, IDMC has installed and commissioned several high capacity fully automated computer-controlled dairy, food processing and pharma plants.

Process engineering & automation

Innovation, experience, and depth of process knowledge allow IDMC to offer a range of process technologies and customized plant design suitable to process liquid milk and manufacture ice-cream, curd and yogurt, butter, paneer, UHT, cheese and other dairy products. Process optimization ensures higher efficiency and enhanced productivity.

IDMC provides complete customized software solutions with the latest hardware and instrumentation.

The SCADA systems of IDMC allow real-time MIS for both processes and utilities, facilitating effective monitoring of plant operations. The instrumentation and automation business of IDMC aims to make the operation of dairy, refrigeration, pharmaceutical and cattle feed projects safer and more reliable. IDMC has a fully equipped, dust-free, climate-controlled panel manufacturing facility to make motor control centres, control panels, remote IO panels and power distribution panels. The facility also houses an automation training centre, equipped with PLC and DCS test kits to train automation engineers.