Fixed Type Bucket Milking Machines for Cows –

One & Two Can Cluster:

The fully indigenous (Make in India) Fixed Type Bucket Milking Machine with one/two can cluster assembly consists of:

- Vacuum pump assembly: 225 LPM capacity complete with vacuum tank, regulator, gauge, three vacuum taps, two bends, and necessary fittings.

- Can cluster assembly: Includes one can and can cover.

- Pneumatic pulsator: Set at 70 PPM with a pulsation ratio of 60:40.

- 300 cc Flexi Claw milking unit: Includes vacuum hose, milk hose, twin pulsation tube, and short pulsation tube.

- Necessary fittings along with cleaning and disinfecting solutions.

Fixed Type Bucket Milking Machines for Buffaloes –

One & Two Can Cluster:

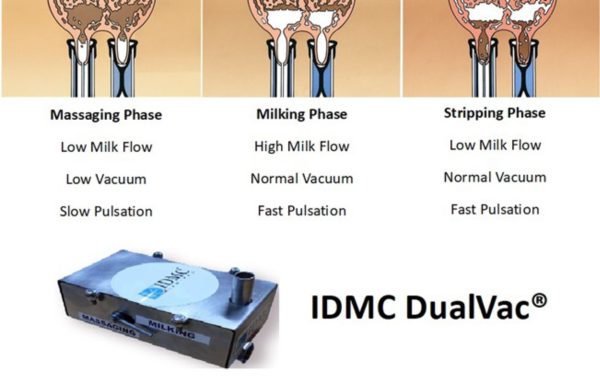

Buffaloes are more difficult to milk than Holstein or Jersey cows due to:

- Small cisternal fraction of milk: Buffaloes store less milk in the udder's cistern, making it harder to extract.

- Stronger sphincter muscles: The muscles guarding the teat canal require higher vacuum levels to open.

Effective milking requires an active milk ejection reflex, which may need stimulation. Considerations for milking buffaloes:

- Milking at a high vacuum without milk ejection can suck the teats deep into the milking liners, preventing milk flow and causing stress.

- Milking at a low vacuum with a lower pulsation rate allows gentle tactile stimulation, promoting natural milk ejection.

Buffalo Milking Cluster

The IDMC Milking Cluster FC300B is specially designed for buffaloes, featuring:

- Stainless-steel claw: Allows additional weight for proper positioning on teats.

- Prevents upward movement: Ensures stability and prevents pulsation failure.

While the other components of the milking machine are similar to those used for cows, the vacuum and pulsation settings are specifically adjusted for buffalo milking.

Mini Milker

IDMC offers a valuable solution for small farm holders to mechanize their farms with the robust, efficient, and economical Mini Milker. This plug-and-play bucket milking machine is ideal for:

- Small farms with one or two cows.

- Milking approximately 6 to 8 cows per hour.

The Mini Milker is constructed entirely of SS 304, ensuring durability and hygiene. It features:

- Low power consumption: Operates on a 0.75 hp motor.

- High-flow vacuum pump: Minimum flow rate of 150 LPM.

- SHIVA pulsator: Specially developed for the Mini Milker, with minimal moving parts for trouble-free operation.

- 300cc Flexi Claw: Enables high milk flow rates even on small farms.

- Easy maintenance and usability: Simple connections and tubes for hassle-free operation.

Models Available: Fixed and Trolley

Main Advantages of Mini Milker:

- Compact and robust: Lightweight yet highly efficient.

- Easy to handle: Designed for farmers' convenience.

General Benefits of Milking Machine

- Easy to Operate: Simple functionality for hassle-free milking.

- Efficient, Hygienic, and Consistent Milking: Ensures cleanliness and uniform milk extraction.

- Comfortable for the Animal: No irritation to teats, tissues, or udders.

- Faster and Better than Hand Milking: Saves time and effort.

- Low Maintenance: Durable design with prompt after-sales service.

- Easy to Maneuver: Trolley model allows smooth movement.