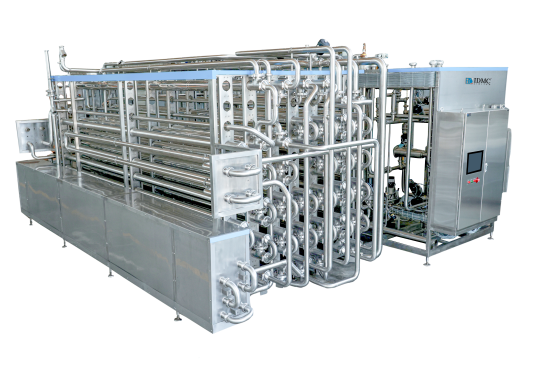

Ultra High Temperature (UHT) Milk Sterilizer

IDMC supplies a skid-mounted Ultra High Temperature (UHT) milk sterilizer, which requires a relatively shorter time for installation and start-up. IDMC offers an indirect method of UHT heating. The brevity of the treatment makes it possible to achieve very high product quality.

This sterilizer is suited for aseptic pouch or other aseptic filling machines or aseptic tanks for UHT milk products, with the flexibility to connect the homogenizer either for aseptic or non-aseptic applications.

UHT Treatment Process

In UHT treatment, the goal is to maximize the destruction of microorganisms while minimizing chemical changes in the product. This requires finding the optimal combination of temperature and processing time for different types of food.

Our state-of-the-art design allows incorporation of all utility equipment such as valves, pumps, and PHE on a skid. The product tank bypass system during sterilization ensures effective utilization of energy.

With indirect heating, the product does not come into direct contact with the heat source but is instead heated using heat exchangers. This method is highly cost-effective because most of the heat energy can be recovered.

This system works on the principle of sterilization, which allows heating milk at ultra-high temperature and then cooling it to ambient temperature for further input into the desired aseptic packaging line.

The UHT sterilizer ensures the correct quality of the end product with its special features and PLC automation controls, enabling flawless operation with minimal manual interference. It is programmed to perform CIP automatically and efficiently.

Advantages:

- Uniform thermal processing.

- Regeneration efficiencies up to 85%.

- Longer production cycles.

- Compact & hygienic designs, customized solutions.

- Low maintenance cost.

- Higher shelf life & product uniformity.

- High response to Cleaning in Place (CIP).

- Minimal spares requirement.

- Saving investment on infrastructure.

Applications:

- Milk

- Flavoured milk

- Cream

- Yoghurt & fermented milk products

- Dairy formulations

Available capacity : Upto 15 KLPH