Inline Shear Mixer (ISM)

This is effectively used for blending dry powder into water or any other liquid.

The Inline Shear Mixer (ISM) effectively forces powder into the liquid stream. This not only allows it to disperse and hydrate large volumes of powders but also can be used at higher temperatures and with higher viscosity mixes.

Inline Shear Mixer is also available in table form as ergo flex shear mixer.

Inherent Features:

- Rapid powder mixing rate of up to 3 tons / Hr.

- Hopper volume: 100 Liters.

- Consistently agglomerate-free product, ensuring uniform mixing every time.

- Suitable for high-temperature operations with exceptional performance.

- Minimum aeration for uniform product quality

- Modular construction offers versatility for various applications and batch sizes

- Low power requirement without the need for additional pumps in case of short suction/distance. Connected power is similar to that of Shear Pump

- Parts in contact with the product AISI 316L (1.4404). Other steel parts AISI 304 (1.4301). Gaskets in contact with the product EPDM/FPM

- Easy to install, operate and clean

Table Blender

IDMC table blender is used to dissolve solids/powders in recirculated liquids. It is equipped with a centrifugal pump and Shear pump in series connected to powder hopper from where the powder is sucked into the liquid.

It is widely used for the reconstitution or stabilization of milk in the production of dairy products, and dissolution of sugar for the production of syrup and also for making Pectin Solution in the beverage industries.

Inherent Features:

- Rapid powder mixing rates of up to 3 tons / Hr.

- Hopper volume: 50 Liters.

- Magnetic grill and also vibratory motor can be provided on the hopper optionally.

- Consistently agglomerate-free product, ensuring uniformity every time

- Suitable for high-temperature operations with exceptional performance

- Minimum aeration for uniform quality

- Parts in contact with the product AISI 316L (1.4404). Other steel parts AISI 304 (1.4301). Gaskets in contact with the product EPDM/FPM

- Easy to install, operate and clean

Bottom Entry Agitators

(IBHA Series)

IDMC offers bottom entry hydrofoil agitators specially designed for efficient and homogeneous mixing of milk. Mounted at the bottom of the tank/silos, these agitators provide direct gentle mixing from the bottom upward, ensuring uniform product consistency.

Bottom entry agitators are ideal for tanks ranging from 20 KL to 150 KL and are designed to meet stringent hygiene requirements while offering ease of cleaning. Each unit features a specially engineered hydrofoil impeller that delivers strong axial flow with minimal turbulence, resulting in high mixing efficiency with low power consumption.

Advantages:

- Uniform bottom-to-top gentle mixing.

- Better cleaning/hygiene compatibility.

- Efficient at low fill levels.

- Easier installation & maintenance

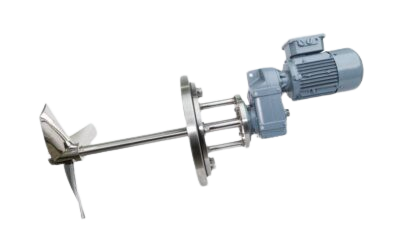

Side Entry Agitators

IDMC offers side entry agitators designed to mix large volumes of liquid efficiently and homogeneously. These agitators prevent sedimentation and maintain temperature uniformity in large tanks. They can be conveniently installed at any position along the side of the mixing tank or vessel. IDMC’s side entry agitators are suitable for tanks ranging from 20KL to 150KL.

The agitators feature a specially designed hydrofoil impeller that generates axial flow without turbulence, ensuring better mixing efficiency with low power consumption.

Advantages of Side Entry Agitators Over Vertical Agitators:

- Lighter in weight.

- Easier to mount.

- More energy efficient.

- Low RPM operation.

- Convenient to transport.

Turbo Blenders

Turbo blenders are widely used for recombination and reconstitution in both food and non-food industries. This versatile equipment from IDMC is ideal for various solid-liquid and liquid-liquid mixing applications. All parts that come into contact with the product are made of AISI 304 stainless steel and/or AISI 316L.

Available capacity: Upto 3500 kgs/hr